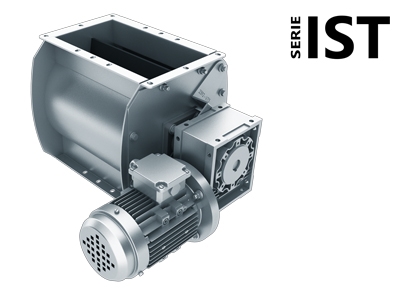

ROTARY WALVES

ROTARY WALVES

VALV-

Revolutins: 18 - 36 [rpm] | Flow rate: 5 - 103 [liters per revolution]

The IST valves are suitable for transporting materials nad waste, all types with the exclusion of abrasive ones and/or corrosive.

■ The valves are supplied with gearmotor or if you need to change the moving laps also with motovariator-gear reducers or motoinverter.

■ The IST valves, being able to vary the length make it possible to carry out silos discharges storage, without making any changes to section or reduction facilitating discharge and batching.

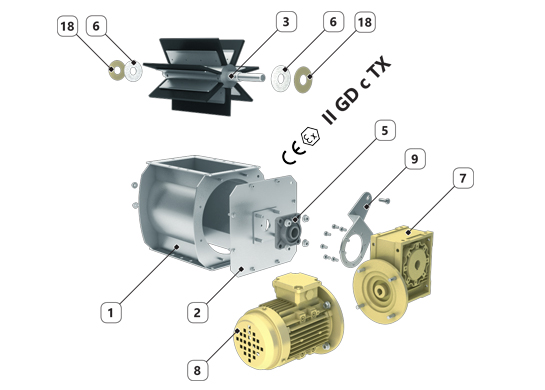

■ ATEX non-sparking version: shims on non-rotating parts potentially in contact with the fan in non-ferrous material.

■ The IST valves can be built in the most different materials and with surface treatments specific to the applications you need.

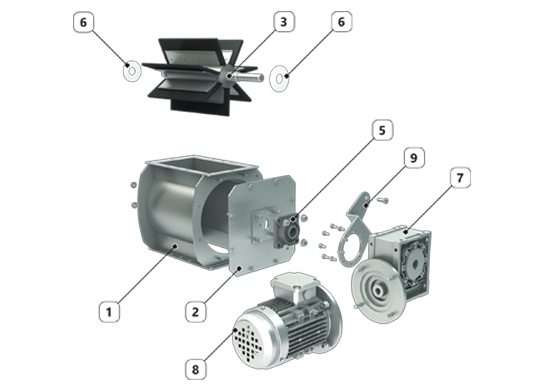

1) Valve body

2) Cover

3) Rotor

4) Mechanical tongue UNI

5) UCF 207

2) Cover

3) Rotor

4) Mechanical tongue UNI

5) UCF 207

6) Felt

7) Gear box

8) Motor

9) Reaction arm

18)Brass shim

7) Gear box

8) Motor

9) Reaction arm

18)Brass shim

Powered by Passepartout

Designed by Gestionale Toscana Srl

Designed by Gestionale Toscana Srl