ROOF EXHAUST FANS

ROOF EXHAUST FANS

V23VSA

Flow rate: 10102 - 77340 [m3/h] | Pressure: 0 - 3 [mmH2O]

The VSA series is particularly suitable for moving large volumes of air with low pressures.

The VSA series has been designed specifically to operate in highly corrosive environments or in environments with abrasive substances.

■ ATEX non-sparking version: shims on non-rotating parts potentially in contact with the fan in non-ferrous material.

■ Anticorrosive execution of paint choirs or special materials.

■ High temperatures with cooling fan up to 300 ° C, special executions on request for temperatures up to 450 ° C.

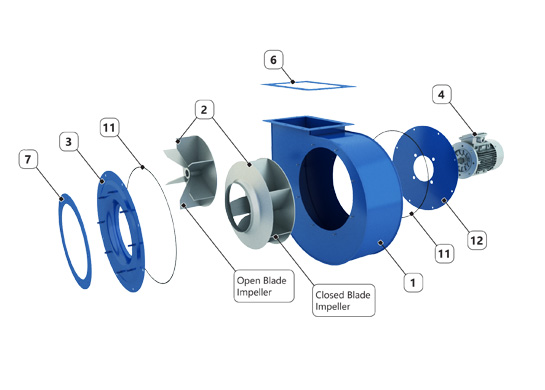

1) Square Washer

2) Puley (big)

3) Belt

4) Puley (small)

5) Electric Motor

6) Motor Support Arm

7) Crossing Hub

8) Standard Arm

9) Bearing + Spacer

10) Blade Hub

11) Blade

12) Box Panel

13) Venturi Nozzle

14) Gravity Shutter

12) Box Panel

13) Venturi Nozzle

14) Gravity Shutter

Powered by Passepartout

Designed by Gestionale Toscana Srl

Designed by Gestionale Toscana Srl